Manage consumables in your procedural area using QSight

Kanban is a QSight module that uses a two-bin solution to simplify inventory management of consumable products such as tubing, syringes, needles, adhesives, and more. Adding Kanban to your QSight solution provides greater visibility and a better, easier way to control costs, improve efficiencies, and lower inventory. And with the combination of Kanban with QSight, you can manage nearly 100% of your inventory in a given procedural area.

QSight Kanban

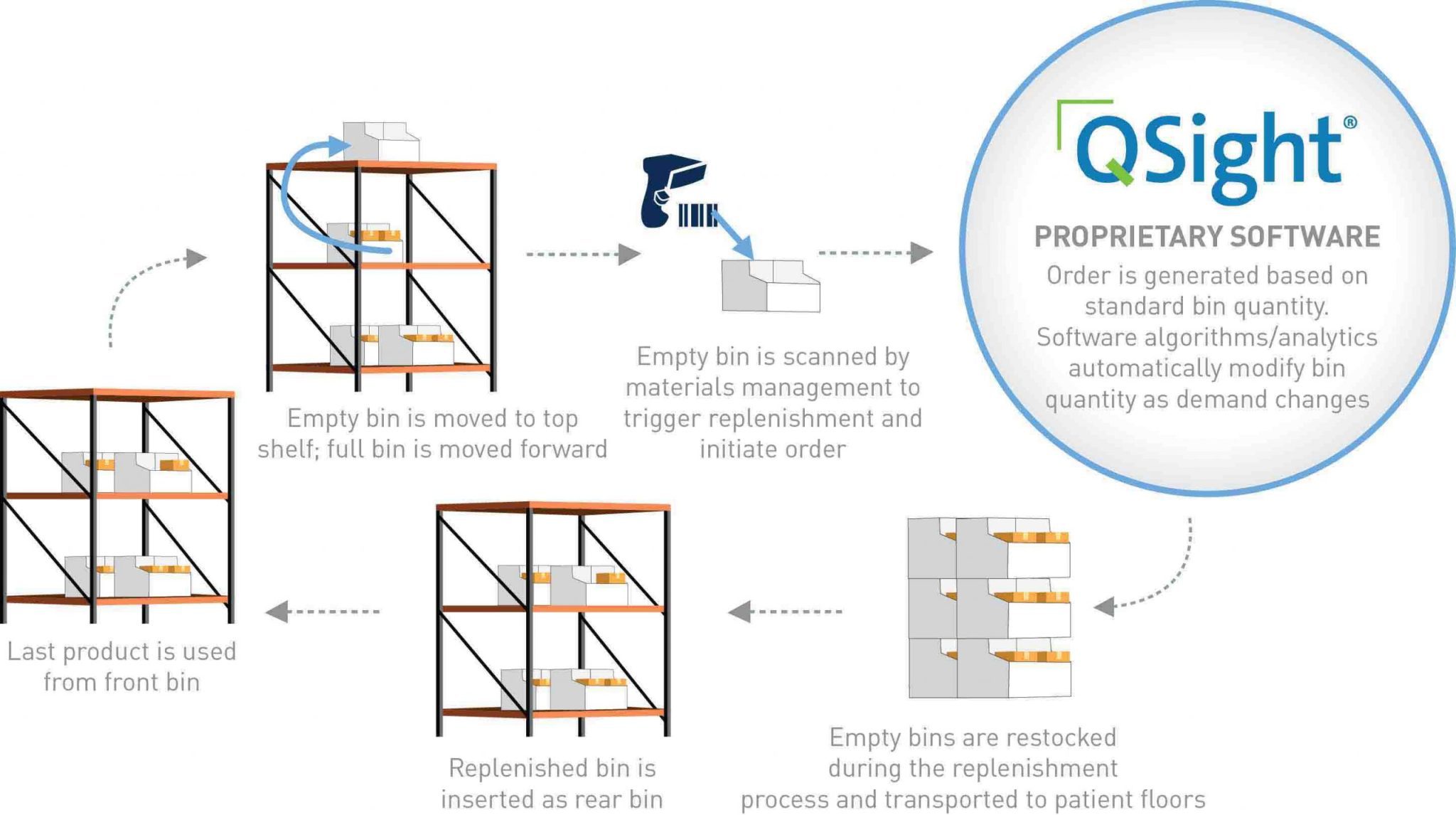

Kanban features an easy-to-use, two-bin solution to manage the inventory of your consumable products in procedural areas of your hospital. Each consumable product is stored in two separate bins on a rack, one behind the other. Clinicians pull product from the front bin and when depleted, puts the bin on the top of the rack and the bin behind it is pulled forward.

The empty bins can then be collected and easily scanned into QSight. This automatically triggers a re-ordering of the product at a pre-set quantity. The replenishment product arrives at the hospital, is placed in bin and conveniently delivered right to stocking locations where it is put behind the existing bin.

QSight Kanban

Kanban features an easy-to-use, two-bin solution to manage the inventory of your consumable products in procedural areas of your hospital. Each consumable product is stored in two separate bins on a rack, one behind the other. Clinicians pull product from the front bin and when depleted, puts the bin on the top of the rack and the bin behind it is pulled forward.

The empty bins can then be collected and easily scanned into QSight. This automatically triggers a re-ordering of the product at a pre-set quantity. The replenishment product arrives at the hospital, is placed in bin and conveniently delivered right to stocking locations where it is put behind the existing bin.

QSight Kanban

Kanban features an easy-to-use, two-bin solution to manage the inventory of your consumable products in procedural areas of your hospital. Each consumable product is stored in two separate bins on a rack, one behind the other. Clinicians pull product from the front bin and when depleted, puts the bin on the top of the rack and the bin behind it is pulled forward.

The empty bins can then be collected and easily scanned into QSight. This automatically triggers a re-ordering of the product at a pre-set quantity. The replenishment product arrives at the hospital, is placed in bin and conveniently delivered right to stocking locations where it is put behind the existing bin.

An Extension of Your Existing Qsight Platform

Backed by the QSight technology team, Kanban is integrated directly into your existing QSight platform so you don’t have to worry about maintaining a separate solution.

Quick and Easy Implementation